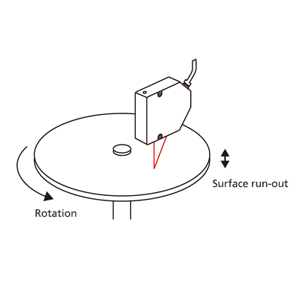

When choosing an optimal solution for measuring run-out / vibration / eccentricity, certain factors should be considered: type of run-out or vibration (direction), type of measuring system that is used and installation environment. Choosing equipment that does not suit your needs can cause insufficient precision and unnecessary increase of working hours in production.

Run-out / vibration / eccentricity measurement

Laser displacement sensor

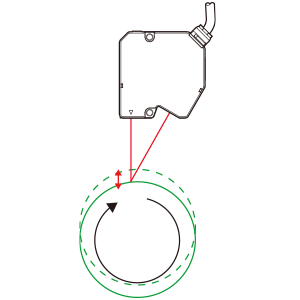

This sensor is used to measure vibration and eccentricity, or oscillations at one point on the surface of the object.

The vibration amplitude rises further from the center of rotation, which facilitates the fluctuation of the recording height. Vibration measurements must be performed at a sampling rate of at least ten times the frequency of the oscillation of the object.

To measure eccentricity, the laser is directed at the top of the circle to capture fluctuations in the distance through high speed sampling. Measurement must be carried out at a sampling rate of at least ten times the speed of rotation. As the shaft diameter decreases, errors increase as the top position moves left or right due to eccentricity.

Examples of applications:

- Measuring rotor vibration

- Measurement of electrode thickness

- Controlling the position of the air knife

- Active measurement of layers on solar panels

- Checking the accuracy of assembling the zoom lens

- Measuring the height of the connector

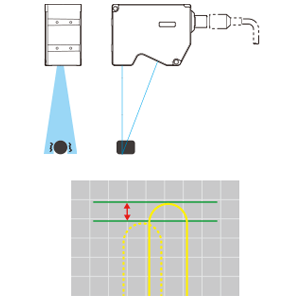

2D Laser Displacement Sensor

The line laser is irradiated on the target and the height of the characteristic point (e.g. peak point) is detected from the obtained shape to measure the run-out amount.

If the peak point shifts to the left and right, the peak cannot be captured at all times if you are measuring by a 1D laser displacement sensor. The peak point can be tracked at any time using the 2D laser shift sensor. Measurement must be carried out at a sampling rate of at least ten times the oscillation frequency.

Examples of applications:

- Final inspection of the welds

- Measurement of deformation / flatness on motherboards, etc.

- Measurement of profile and cross sections

- Determining the width and position of the measuring object (e.g. cutting plates)

- Measuring the angle of the processed products

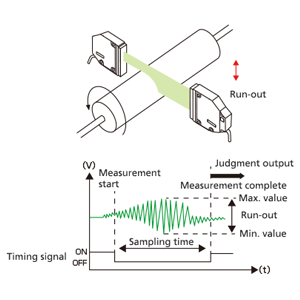

Thrubeam 2D optical micrometer

The eccentricity is mesured by finding fluctuations at the position of the specified multiple points from the image obtained by the 2D optical projection method.

The run-out of V grooves and protrusions in the circumference can be measured, as well as the run-out of a point at a predetermined distance from the end.