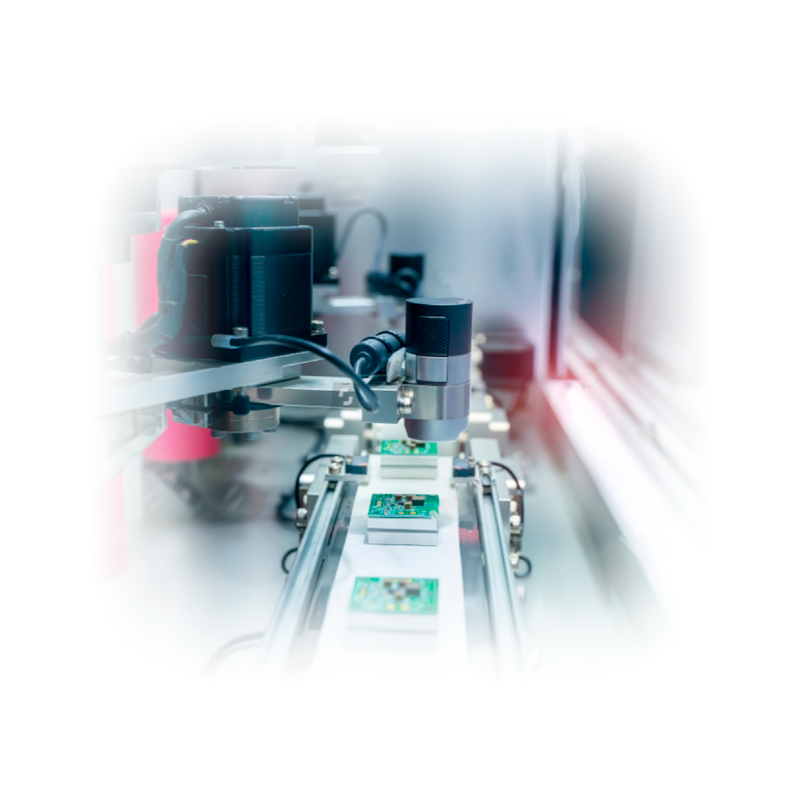

Height is measured by detecting the position of an object’s top surface. For objects with bottom surfaces that are not fixed, shapes are directly measured by using two sensors or by projecting the laser in a horizontal line.

Height measuring

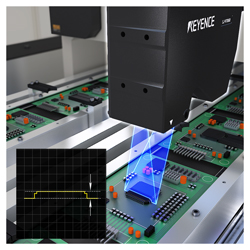

Light-Cut method

The position of an object’s top surface is detected.

The ability to perform non-contact 2D profile measurements makes it possible to perform step measurement with respect to a reference plane on the target.

- Possible to measure 2D height within a line

- Unlimited target selection at ultra-high speeds

- Ability to output waveform data

- Non-contact measurement

- Measurement of X, Y and Z levels at the same time

- Ultra high speed sampling, up to 240 times faster than conventional methods, measurement of a moving object

Application examples:

- Final inspection of the welds

- Measurement of deformation / flatness on motherboards, etc.

- Measurement of profile and cross sections

- Determining the width and position of the measuring object (e.g. cutting plates)

- Measuring the angle of the processed products

- Measuring the thickness of the housing

Confocal Reflection Method

Measurement of thickness is done using two sensors placed up and down, between which the part is placed to measure. If part is transparent, measurement can only be performed with one sensor set up or down.

- High-accuracy non-contact measurement of various target materials and colors

- Ultra-compact and lightweight for easy installation

- High accuracy across a wide measuring range

Primeri aplikacija:

- Thickness of film and foil for packaging

- Thickness of glass panels

- Thickness of various materials (plastics, metal, black rubber, gel, mirrors, sealants, adhesives, etc.)

- Thickness of printed boards

- Measurement of machine-made parts (e.g. brake discs)

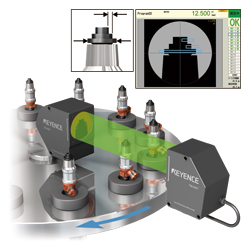

Optical Thrubeam Method

By capturing the shadow of a target’s shape, the sensor can detect any position. Simultaneous measurement of multiple points is also possible.

- Measurement possible at multiple points simultaneously

- Highly stable

Application examples:

- Measurement of total width and angle on springs

- Measurement of the outer diameter and angle of the top of the valve

- Measurement of the outer diameter and angle of the tip of medical needles for syringes

- Measurement of the diameter and height of the lens

- Measurement of the maximum and minimum ampoule diameter

- Measuring threads on PET bottles

- Measurement of the diameter O of the seal

Contact-Type

Heavy and robust digital contact sensor for general purpose with calibration buttons.

- Sturdy, robust: IP-67 degree of protection

- simplified setup

- Adjusting the zero point with a single push of a button

- Data communication with 10 amps

- Selecting a target is determined only by firmness

- Possibility of precision measurement

Measurement of the thickness is done using two sensors, between which the object of measurement is set. The measurement method by the contact method allows for high accuracy of measurement. Suitable for implementation in automatic, semi-automatic and manual machines, compact and easy to install because it requires very little space.

Examples of applications:

- In the automotive industry for measuring the external / internal diameter of the components, inspection of discs, loss on camshafts, checking the level of the engine block / oil tank

- In metalworking industry for checking the completeness of bearings, dimensional measurement during metal processing

- For electro components, checking the flatness of the battery, the basics of the smartphone phone, checking the completeness of motherboards, hard drives and the like

- Measurement of thickness / height / plane of semiconductor and liquid crystals

In the food industry, checking duplicated labels / labels, product overload, etc.